주)페트로산업 메인 네비게이션

페트로산업 sub navigation

Non-exposed Tar Urethane (PU-N)

|

Strengths

Use

Packaging Unit

Mix Proportion

|

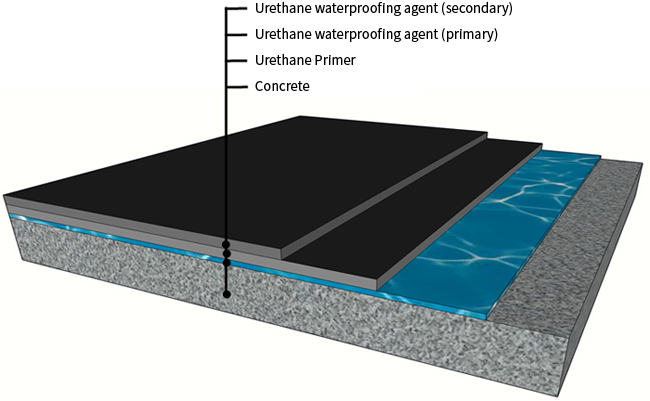

Construction Floor Plan

|

Quality Standard

- KS F 3211 (2015) : Construction Film Waterproofing material

| Item | Performance Standard | |||

|---|---|---|---|---|

| Tensile Performance | Tensile Strength Tensile Strength (N/㎜²) | Above 2.0 | ||

| Coefficient of Expansion (%) | Above 550 | |||

| Tensile Product (N/㎜) | Above 294.2 | |||

| Tearing Performance | Tearing Strength (N/㎜) | Above 12.8 | ||

| Reliability on Temperature | Tensile Strength Ratio (%) | -20 ℃ |

Above 100 | |

60 ℃ |

Above 35 | |||

| Coefficient of Expansion between engagement portion during rupture (%) |

-20 ℃ |

Above 300 | ||

20 ℃ |

Above 350 | |||

60 ℃ |

Above 200 | |||

| Heat Expansion Characteristic | Expansion Rate (%) | Above -4, Below 1 | ||

| Tensile Performance | Tensile Strength Ratio(%) | Heat Treatment | Above 80, Below 150 | |

| Promotional Exposure Distance | - |

|||

| Alkali Treatment | Above 60, Below 150 | |||

| Acid Treatment | - |

|||

| Coefficient of Expansion (%) | Heat Treatment | Above 500 | ||

| Promotional Exposure Treatment | - |

|||

| Alkali Treatment | Above 500 | |||

| Acid Treatment | - |

|||

| Deterioration during Elongation | Heat Treatment | There shall be no fractured balance or apparent deformation of any test. |

||

| Promotional Exposure Treatment | - |

|||

| Ozone Treatment | - |

|||

| Adhesion Performance | Untreated | N/㎜² |

Above 0.7 | |

| After Repeated Cold Temperature Treatment | Above 0.5 | |||

| Coating State | No lifting or detachment of the coating shall be allowed on any test specimen. |

|||

| Fatigue Resistance | There shall be no perforation, tear, or fracture of the coating on any test specimen specifimen. |

|||

| Flow Resistance Performance | Flow Length (㎜) | No more than 3 on any test specimen | ||

| Crease Formation | Not on any test specimen. | |||

| Solid (%) | Indicator Value ±3 | |||

Construction Method

1. Arranging Grounding Impregnation |

|

2. Apply Primer |

|

3. Mixing Urethane |

|

4. Apply urethane |

|