주)페트로산업 메인 네비게이션

페트로산업 sub navigation

NT Sheet (NT-3000)

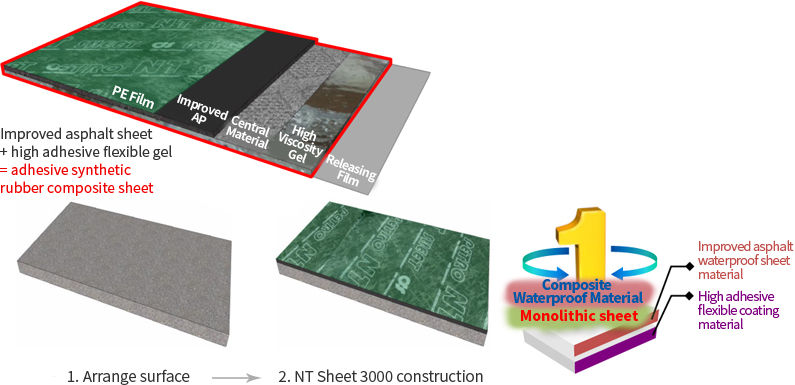

Environmentally friendly waterproofing method for construction without use of separate primers and heat appliances with high-point synthetic rubber composite sheet that combines advanced asphalt waterproof sheet materials with adhesive flexible rubber asphalt coating materials with high tensile strength, heat resistance, etc.

Characteristics

- Integrated technology that combines high-adhesive flexible rubber asphalt coating material with improved asphalt sheet (complex waterproofing method)

- Ensure stability of adhesion due to high-adhesive flexible type features

- Ensuring integration of joint between asphalt compounds

- Eco-friendly waterproofing method without separate primers and heat fixtures

- Expecting Air Reduction Effect due to Simplification of Work

- Ensure material environmental stability, such as VOCs and heavy metals

|

Scope of application

Packaging Unit

|

|

Quality Standard

- Improved asphalt waterproof sheet : KS F 4917(2016)

| Classification according to use | Non-exposure layer waterproof | |||

|---|---|---|---|---|

| Classification according to material composition | TYPE A | |||

| Tensile Performance | Tensile Strength (N/㎜) | Untreated | Above 8.0 | |

| After heating | Above 80% of untreated test value | |||

| After soaking alkali | ||||

| Coefficient of Expansion (%) | Untreated | Above 15 | ||

| After heating | Above 80% of untreated test value | |||

| After soaking alkali | ||||

| Tensile Product (N·%/㎜) | Untreated | Above 250 | ||

| Tearing Performance (N) | Above 20 | |||

| Heat Resistance Performance | Roll Down Length (㎜) | Below 5 | ||

| Appearance | Will not roll down or shoot out. | |||

| Fatigue Performance | Will not rip, crack, or be blocked | |||

| Dimensional stability | Change Rate of value (%) | 0.0±1.0 |

||

| Appearance | No creases, bending, or detachment between layers | |||

| Joint Performance (N/㎜) | Above 5.0 or above 70% of untreated tensile strength | |||

| Pitting Performance | No Hole | |||

| Classification according to temperature characteristic | Category 2 | |

|---|---|---|

| Curve Performance | Untreated | No cracks at -15℃ |

| After heating | No cracks at -5℃ | |

- High Adhesive Flexible Gel

| Test Items | Unit | Test Method | Performance STandard | |

|---|---|---|---|---|

| Solid | % | KS M 3705 | Above 85 | |

| Viscosity | cPs | KS M ISO 2555 | Above 2,000,000 | |

| Permeability Resistance performance | - | KS F 4935 | Will not leak | |

| Moisture Adhesive Performance | - | KS F 4935 | The base of the test specimen will not be removed within 60 seconds. | |

| Operation of structure Responsiveness |

When produced at the factory | - | KS F 4935 | Will not be permeated |

| Sheet that has entered the site | - | KS F 4935 Test Method of design standard |

||

| Water Loss Resistance Performance | % | KS F 4935 | Mass change rate shall be within 0.1% | |

| Chemical Resistance Performance | % | KS F 4935 | Mass change rate shall be within 0.1% | |

| Ozone Reliability Performance | - | KS F 4935 | Will not be permeated. | |

Transportation and Storage

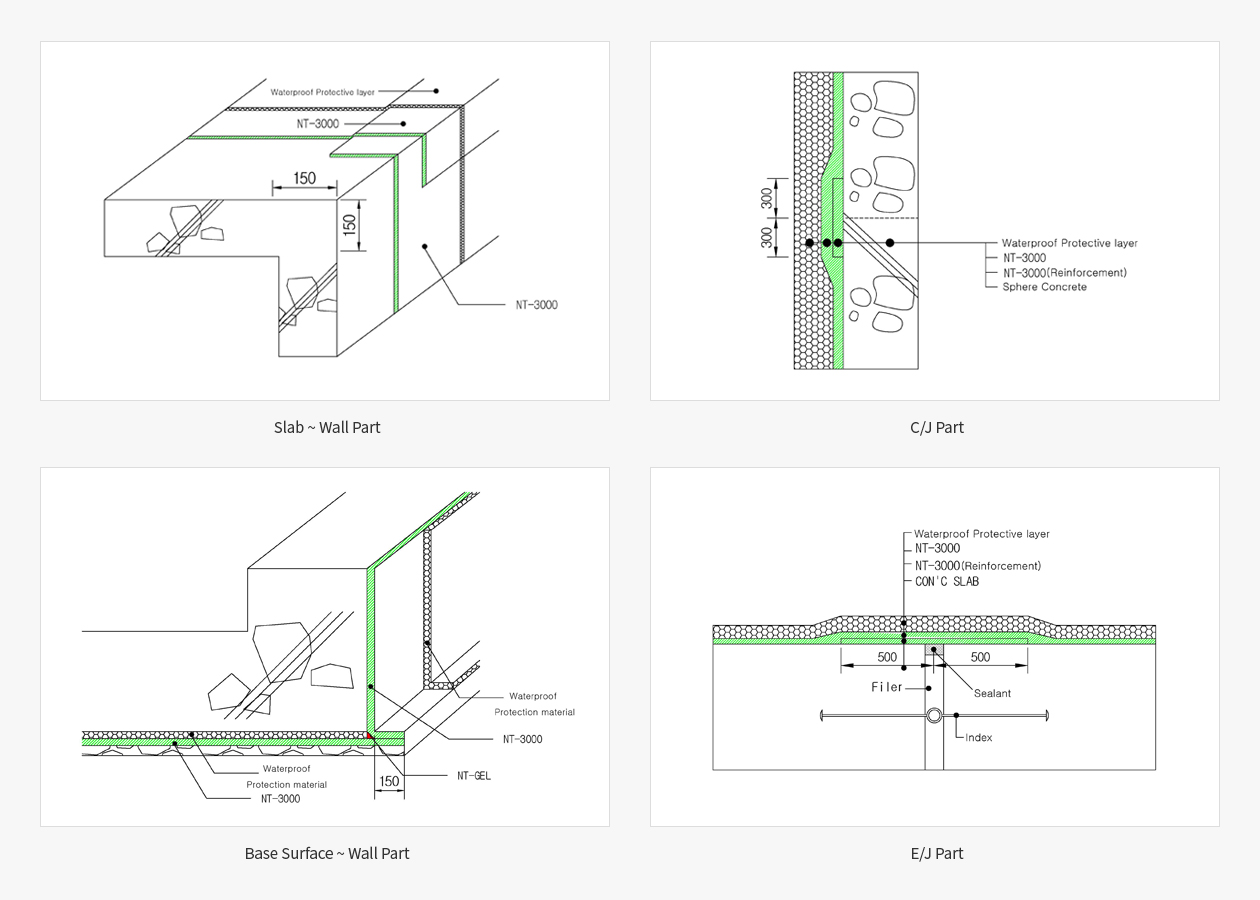

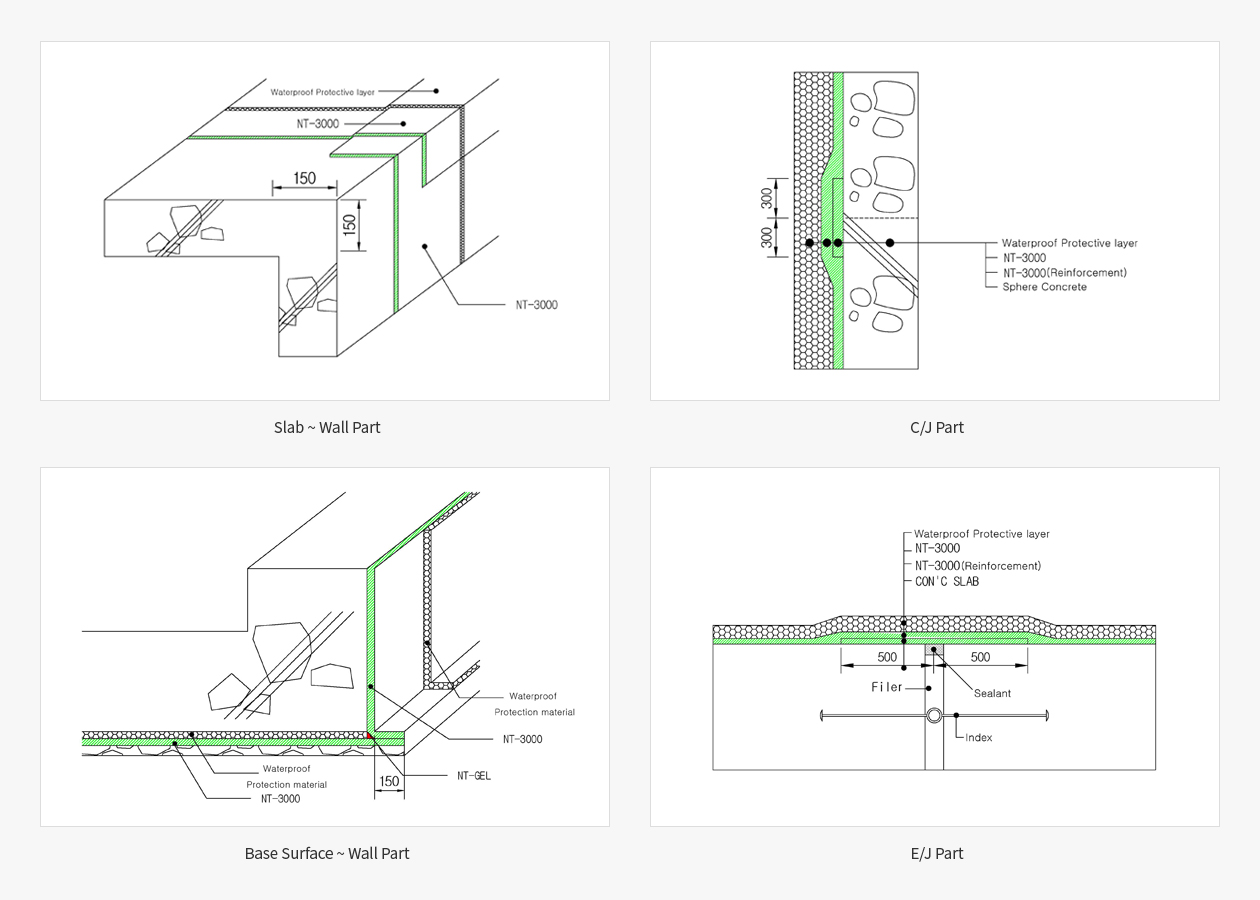

Construction Details